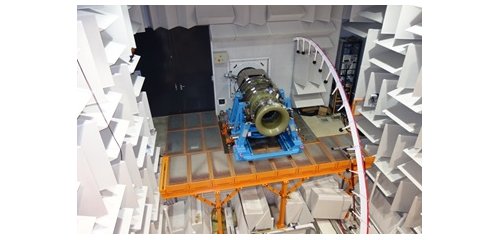

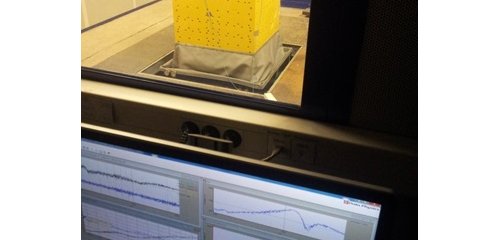

La plate-forme PHARE va permettre à chacun des partenaires de réaliser des développements scientifiques qui leur étaient, jusqu’alors, interdits. En effet, l’absence de données expérimentales en liaison avec des configurations de situations extrêmes empêche la construction de modèles numériques fiables. Ce nouvel équipement va permettre à chacun des partenaires de mieux comprendre les mécanismes physiques prenant naissance lors d’une mise en instabilité mécanique ou aérodynamique, d’un processus de rupture ou de tout autre phénomène conduisant à des comportements hors normes. La plate-forme ayant été conçue pour des turbo-machines réalistes, elle fournira des données directement exploitables pour les situations dans lesquelles ces machines sont utilisées.